Easily improve workplace safety and optimise your performance

Colour your way to an improved workplace with the S3700 Sign and Label Printer. With multicolour print and shape cutting capabilities, this printer creates impactful identification that fits your application and workspace needs. Because safety and efficiency are the pulse of your operations, you need an industrial label printer that delivers both. Put multicolour brilliance, […]

Easily create compliant, safe and efficient workplaces

Complete solutions for all your workplace safety needs from just one partner? Meet Brady Safety Experts at Health and Safety Event 2022! Every workplace accident generates cost, and potentially includes a severe human toll that impacts morale and productivity. Managing safety risks to prevent workplace accidents from happening is both a humane and an economically […]

CASE STUDY: How to significantly improve safety when working at height

Read about the project of Scafftag at Bancroft, where working at height is much safer now thanks to status tagging system and lockout devices. With 150 directly employed staff working on fast track fit-outs at any one time across the South East, health and safety has to be a priority for mechanical and electrical services […]

CASE STUDY: Increase food and employee safety with pipe markers

Read how Brady Corporation helped its customer Woodlands Dairy to optimise food safety, workplace safety and efficiency with reliable and fully compliant labels and pipe markers… Woodlands Dairy is one of the largest manufacturers of UHT milk in South Africa, marketed under their brand FIRST CHOICE®. Brady visited Woodlands Dairy several times to meet with […]

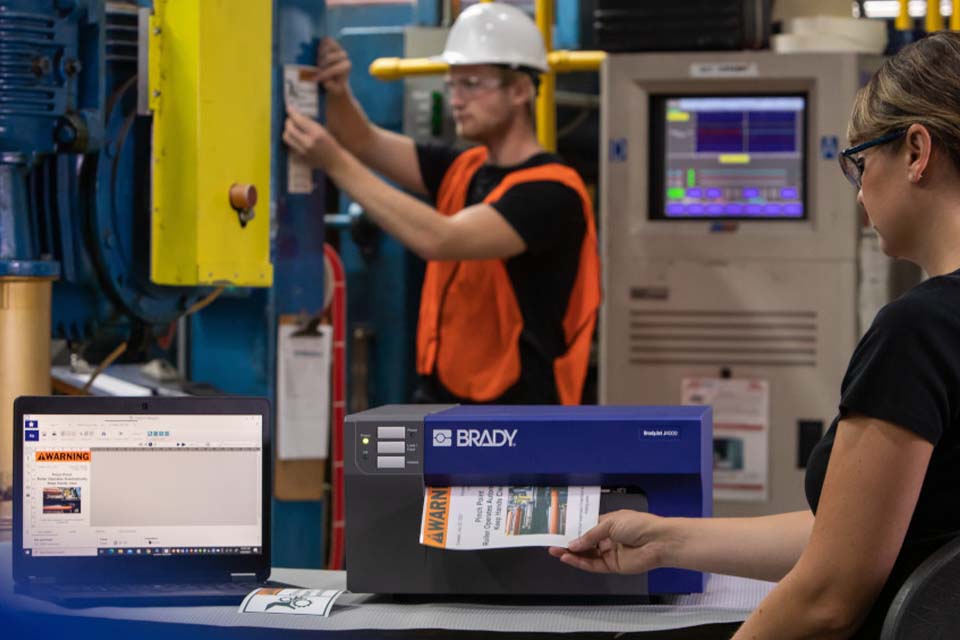

Impact safety with full colour precision signs

Discover BradyJet J4000 Colour Label Printer Create a safer, more efficient workplace with compliant, photo-quality full-colour labels, signs and procedures that last. Balance the complexity of safety and compliance labels with the demands of an industrial environment while reducing your safety signage inventory and material waste. Discover BradyJet J4000 Colour Label Printer! Features & Benefits: Create compliant […]

Easily identify wet, cold or condensed surfaces

By Brady Easily apply reliable pipe markers to wet, rainy and cold outdoor pipe surfaces to make them compliant with any regulation or standard. Wet and condensed surfaces are notoriously difficult to label in a reliable way. Labels tend to get saturated and fall off quickly. Brady’s material B-7530 however stays attached and remains legible. […]

Don’t let safety slip

Winter is not the safest season. Slips & falls increase dramatically, especially when working outdoors, or simply walking to an office from the parking lot. When the cold and dark seem to conspire against health and safety, highlight your new safety communication to lower the risks. Discover safety solutions from Brady and make the winter […]

Faster equipment safety inspections

By Brady Corporation Brady’s SafeTrak makes time consuming paper based equipment inspections a lot faster. Planning, inspecting and reporting can be streamlined, customised and largely automated in the SafeTrak app to save time. Digital support for equipment inspections SafeTrak enables you to keep track of inspections digitally and eliminates the need to make time consuming duplicates, […]

See a face, not an object! Because safety is personal

By Brady Corporation See a person instead of an object by printing a face directly on your Lockout/Tagout padlocks. Build on the one person, one lock, one key principle for maximum Lockout/Tagout safety! Find out how to fully personalise padlocks. A Lockout/Tagout padlock is often the last obstacle to prevent a premature machine energisation, and […]

Clear visibility of equipment status at the point of use

By Brady Increase inspection efficiency with Scafftag’s reliable holders and inserts that can communicate the safety status of any type of equipment at the point of use. Scafftag holders and inserts can communicate best practice inspection procedures on the equipment that needs inspection. Both the holders and removable inserts are highly customisable and can support […]